The world of automotive lore is filled with quirky jargon, much of which can be unfamiliar to those who have never encountered the subject matter or topic of a particular conversation first-hand. For example, the term “throwing a rod” is commonly used when discussing engine related matters, though not every motorist is keen on the exact meaning behind this phrase.

The world of automotive lore is filled with quirky jargon, much of which can be unfamiliar to those who have never encountered the subject matter or topic of a particular conversation first-hand. For example, the term “throwing a rod” is commonly used when discussing engine related matters, though not every motorist is keen on the exact meaning behind this phrase.

If you are unfamiliar with this phrase, you should consider yourself lucky. Those who have experienced such a situation first-hand will likely never forget it, and for quite the unfortunate reason. However, for the sake of education, the following guide will describe the condition of a thrown rod in detail as well as a number of possible causes for such failures.

What Is a “Thrown Rod?”

The term “thrown rod”, is used to describe the complete structural failure of an engine’s connecting rod (piston rod) or related fasteners, almost assuredly with dire mechanical consequences. In essence, a thrown rod indicates an engine failure of the worst possible type.

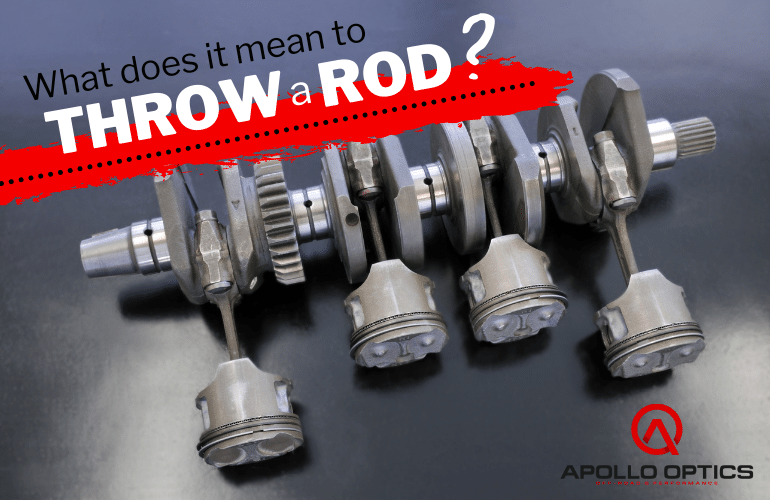

A standard internal combustion engine utilizes a sizable rotating assembly, which includes connecting rods, pistons, and a crankshaft. All of these components are located within the engine block. Atop this block rests a cylinder head(s), which caps the top of each cylinder. A head gasket resides between the engine block and cylinder head to prevent compression loss.

As combustion takes place, the piston within a given cylinder is forced downward in what is known as the power stroke. This piston is attached to its connecting rod via a wrist pin. The connecting rod is also coupled to the engine’s crankshaft at its lower end and rotates on a rod bearing that is held in place by the unit’s rod cap.

The downward motion of a cylinder’s piston and connecting rod rotates the crankshaft, which is mechanically coupled to a vehicle’s driveline components by way of the transmission. The cumulative effect of the rotational force applied to the crankshaft by all of the engine’s pistons/connecting rods is enough to set a vehicle in motion.

However, an engine’s connecting rods bear a significant load and come under tremendous stress during day-to-day operation. Though rare, a connecting rod can fail, often causing irrevocable damage to an engine in the process. The likelihood of such catastrophic failure is greatly increased when an engine is neglected or repeatedly placed under an extreme load.

The Aftermath

The aftermath of a thrown rod is never pretty, often leaving both an engine block and the ground beneath soaked in oil. There is no way to predict how an engine’s rotating assembly will react when a rod breaks. A broken rod often continues along its current path of movement, wiping out all in its way.

In some cases, a thrown rod will result in a piston being projected upward into the bottom of the cylinder or piston head. In other cases, the lower end of a connecting rod can knock a hole in the engine’s oil pan if the rod/piston is approaching the bottom of its stroke at the time of failure. In the most extreme of cases, a piston and rod can be expelled through a cylinder wall and outward through the engine block itself.

In any event, a thrown rod will almost certainly spell the end of the line for an engine, as there is no DIY repair capable of remedying the situation at hand. Unfortunately, the expensive purchase of a new or remanufactured engine is the only viable means of returning your vehicle to service.

Causes of a Thrown Rod

Luckily, throwing a rod is far from the typical everyday occurrence. In fact, such a failure is quite rare, and many motorists will never experience such misfortune. Throughout nearly 100 years of automotive production, a wealth of advancement has been made in the materials and craftsmanship which goes into the construction of every engine on the road today. Modern internal combustion engines are quite hearty and can withstand an extensive amount of stress with little issue.

However, a neglected engine is still prone to catastrophic failure. While a limited number of modern engines have thrown rods as the result of structural fatigue, the vast majority of such failures are set into motion by a number of less complex issues which have been overlooked or ignored.

The following are the top causes of connecting rod failure.

Low Oil

An engine that lacks sufficient crankcase lubrication is virtually guaranteed to suffer premature failure. An internal combustion engine relies upon engine oil to lubricate nearly all of its moving parts. Without this lubrication, friction occurs, and excess heat builds. With time, a weak link is found, and engine failures is swift to follow.

A lack of lubrication can lead to the binding of piston rings as well as a heat build-up within a piston’s skirt, which ultimately leads to thermal expansion. If oil starvation is severe enough, low oil pressure will result, causing excess wear to main and rod bearings. Badly worn rod bearings can also create damaging slack within an engine’s lower rotating assembly. In many instances, rod knock, or a loud metallic knocking sound will be heard shortly before complete component failure occurs.

It is absolutely imperative to check your engine’s oil level from time to time to ensure that its oil is topped off as specified. This is especially true if an engine is known to burn oil or have an oil leak.

Overheating

An engine that significantly overheats or overheats on a repeated basis is also prone to catastrophic internal failure at a moment’s notice. An engine’s components are designed with a set operating temperature range in mind. When these components exceed these temperatures, undue stress and premature wear results. In severe cases, connecting rods and wrist pins can shear, leading to a thrown rod.

Overheating typically occurs as a result of low coolant/antifreeze levels. Coolant dissipates heat as it circulates through an engine’s block and cylinder heads before returning to the vehicle’s radiator. If coolant levels drop below a certain threshold, overheating becomes imminent.

It is essential to check and top off your vehicle’s coolant level on a regular basis. If an inspection of this nature reveals a loss of coolant, the source of any leaks should be uncovered and remedied before becoming worse. A minor coolant leak can worsen at any time, thereby leading to damaging overheating in the process.

Over Revving

Bouncing your engine’s RPMs off of the rev limiter is never a good idea if a lengthy service life is of any concern. Neglecting an engine can quickly turn a fun day on the track or trail into a long ride home behind a wrecker of your choice. In the end, a few seconds of light-hearted enjoyment can end up costing thousands of dollars.

Over revving your vehicle’s engine is like trying to beat a train across the tracks. While nothing bad might come out of such actions on nine out of ten occasions, it only takes one instance of misfortune to leave everything in ruin.

As an engine begins to age, normal component wear often leaves an engine long in the tooth. Bearing tolerances find their way out of spec, cylinder walls start to wear, and less room for error exists than when a vehicle was fresh off of the dealership lot. Pushing an engine to its extreme, such as when standing on the accelerator pedal, tends to expose these vulnerabilities in the worst kind of way.

Additional Internal Component Failure

In certain instances, an engine can throw a rod as the result of a chain reaction. Inside an engine, there is little room for error, and when the smallest of components give way, significant damage is almost sure to follow. Though extremely rare, a rod bolt can shear off or work loose, releasing a connecting rod from its point of mount atop the crankshaft. When this occurs, the wayward connecting rod and piston will continue on their current path of travel until impacting a surface with enough mass to prevent further travel.

In other instances, a dropped intake or exhaust valve can impact the face of a piston, doing substantial damage. If the face of this piston were to crack, the piston itself could wedge within its cylinder bore until the rotational force of the crankshaft breaks the attached connecting rod or wrist pin.

Unfortunately, there is little way to predict the occurrence of such issues. While one could drop their vehicle’s oil pan to ensure proper rod bolt torque or remove their engine’s valve cover to inspect the valve springs and keepers beneath, there is no guarantee that failure of this type will not occur at a later date. Luckily, mishaps of this type tend to be few and far between.